A Revolutionary Approach to “Greening” the Chemical Industry

Liquid metals could be the key to transforming the chemical industry, as researchers from the University of Sydney present a groundbreaking technique. This new method, using Gallium liquid metal, promises to replace old, energy-intensive chemical engineering processes dating back to the early 20th century.

Chemical production is a significant contributor to greenhouse gas emissions, accounting for about 10-15 percent of the total. It also consumes more than 10 percent of the world’s energy, primarily in chemical factories. But a new study published in Nature Nanotechnology introduces an innovative solution that veers away from traditional, energy-intensive solid catalysts.

The Liquid Metals Research and Its Implications

The research, led by Professor Kourosh Kalantar-Zadeh and Dr Junma Tang from the University of Sydney’s School of Chemical and Biomolecular Engineering, reimagines the use of catalysts in chemical reactions. Traditionally, solid metals or compounds have been the norm, but these require high temperatures, often reaching a thousand degrees centigrade.

Contrastingly, the new process involves liquid metals, specifically dissolving tin and nickel into them. This approach allows for unique mobility, facilitating reactions at the surface with input molecules like canola oil. The result is the rotation, fragmentation, and reassembly of canola oil molecules into smaller organic chains, including propylene, a crucial high-energy fuel for many industries.

Professor Kalantar-Zadeh said their method offers an unparalleled possibility to the chemical industry for reducing energy consumption and greening chemical reactions.

He further emphasizes the urgency of this innovation, predicting that chemical sector emissions could rise to over 20 percent by 2050. The chemical manufacturing industry, often less visible than others, requires a paradigm shift, he suggests.

How the Process Works

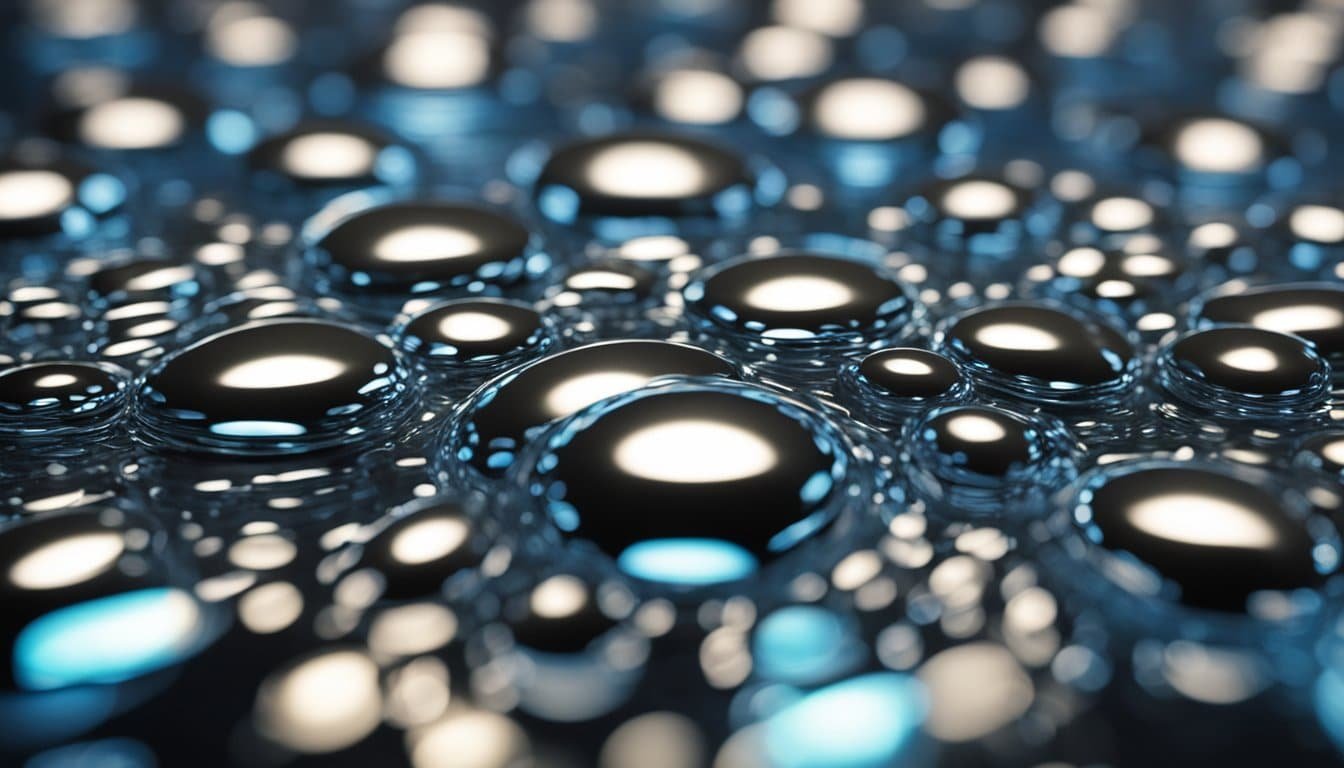

Atoms in liquid metals are more randomly arranged and have greater freedom of movement than solids. This allows them to easily come into contact with, and participate in, chemical reactions. Kalantar-Zadeh said that theoretically, they can catalyse chemicals at much lower temperatures – meaning they require far less energy.

In their research, the authors dissolved high melting point nickel and tin in a gallium-based liquid metal with a melting point of only 30 degrees centigrade.

Dr. Tang explained that by dissolving nickel in liquid gallium, they were able to access liquid nickel at significantly lower temperatures, which functioned as an exceptionally effective catalyst. He noted that while solid nickel melts at 1455 degrees centigrade, liquid gallium allows for a similar, albeit less intense, effect with tin metal.

The researchers noted that their formula could also be used for other chemical reactions by mixing metals using the low-temperature processes.

Dr. Tang humorously remarked that the catalysis process they developed requires such a low temperature that, in theory, it could be conducted on a gas cooktop in a kitchen, but cautioned against trying this at home.

DOI: 10.1038/s41565-023-01540-x

Related:

- The Inventory Days on Hand metric is essential for businesses as it reflects the company’s liquidity and operational efficiency.