Fundamentals of 3D Printed Meat

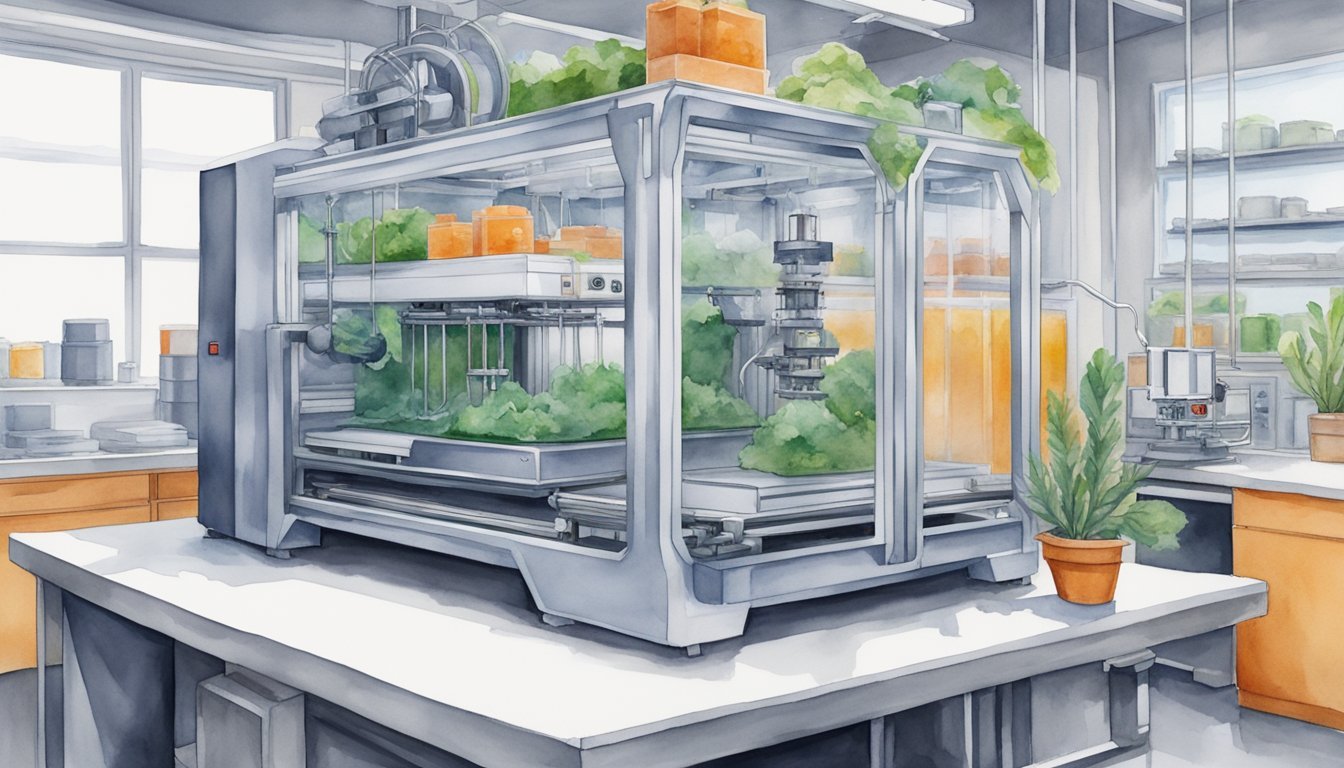

3D printed meat is a groundbreaking development in the field of food technology that intertwines tissue engineering and culinary arts. At its core, it opens the door to sustainable solutions for food production without the need for traditional livestock farming practices. This approach is often referred to as cultured meat or lab-grown meat, and it utilizes bioprinting, a process akin to 3D printing but with organic materials.

Bioprinting of meat begins with the collection of animal cells, which can include a combination of muscle cells and stem cells. Once cultivated, these cells are meticulously layered to create structure. This method fosters the growth of muscle fibers and fat in a controlled environment, resulting in a product that replicates the texture and marbling of conventional meat.

To achieve desired taste and texture, 3D printed meat requires precise manipulation of muscle and fat. Scientists and chefs work together to fine-tune the balance, aiming for a level of marbling comparable to what one would find in high-quality cuts of steak. This method not only minimizes the environmental impact but also bypasses issues related to animal welfare.

The food’s texture is enhanced through varied techniques, such as scaffolding and the correct alignment of printed muscle fibers. It is crucial to ensure that the resulting product closely mimics the sensory experiences expected from an animal-based product.

Before reaching the consumer, 3D printed meat must undergo regulatory approval, ensuring that products are safe, nutritious, and produced according to required standards. Agencies such as the FDA and USDA are responsible for the oversight of these products in the U.S.

In the realm of the future of food, 3D printed meat presents an exciting potential, promising a slaughter-free and environmentally friendlier alternative to traditional meat production. As society continues to explore these innovations, 3D printed meat may well become a staple on dinner plates worldwide.

Innovations and Market Players

The landscape of 3D printed meat is rapidly evolving, with technological advancements propelling industry players towards satisfying global meat consumption in sustainable ways.

Technological Advancements

3D printing technology is revolutionizing the field of alternative meats, merging bio-ink with cells such as those from plants or animals to replicate the histological structure of traditional meat. Techniques like 3D bioprinting foster the development of products with the desired texture, flavor, and tenderness, closely mimicking conventional meat.

Leading Companies and Research

The field boasts numerous front-runners, such as Aleph Farms, which is pioneering in creating steak, and Redefine Meat, known for plant-based meat alternatives. Shiok Meats is venturing into seafood with their 3D printed shrimp, while research at institutions like Osaka University is advancing cellular aquaculture.

Consumer Experience

Alignment with traditional meat’s umami taste and mouthfeel is crucial. Companies like Novameat and Steakholder Foods, previously known as Meat-Tech 3D, emphasize customizability to cater to consumer preferences, enhancing the dining experience.

Impact on Environment and Society

The adoption of 3D printed meats presents a sustainable solution that can reduce greenhouse gas emissions, minimize food waste, and mitigate the strain on the food supply chain. The Good Food Institute promotes these alternatives due to their lower impact on the environment compared to conventional livestock farming.

Global Presence and Regulation

The global demand for 3D printed meat is surging, with Singapore leading as the first country to grant regulatory approval. Companies are scaling operations to meet this demand while navigating the complexities of international food industry regulations.

Future Prospects and Challenges

Scaling production to meet global demand without compromising quality remains a challenge. With ongoing research and development, the future of food looks towards a sustainable fusion of technology and biofarm practices. The ultimate goal is a closed-loop food production system with minimal environmental impact.