Understanding Gum Ingredients

Natural and Synthetic Gum Bases

Gum base is the main component of chewing gum that provides its chewable, rubbery texture. Both natural and synthetic gum bases exist. Some traditional examples of natural gum bases include chicle from the sapodilla tree, and mastic resin from the mastic tree.

In modern times, natural gum bases have been largely replaced by synthetic versions. These alternatives include materials like polyvinyl acetate and butadiene-styrene rubber. Synthetic gum bases have become more popular due to their desirable, consistent properties and their ease of production.

Varieties of Sweeteners

Sweeteners play an essential role in enhancing the taste of chewing gum. A wide range of sweetening agents can be used, from natural options like sugar and honey to artificial sweeteners such as aspartame, sucralose, and xylitol. Some chewing gum manufacturers may use a mixture of sweeteners to obtain an ideal flavor profile.

Flavorings and Taste Enhancers

Chewing gum wouldn’t be enjoyable without delicious flavors. Flavorings can be derived from natural sources, such as fruit extracts and essential oils, or artificially synthesized. Some popular flavor options include mint, fruit, and cinnamon.

In addition to flavorings, taste enhancers may be added to maintain a long-lasting taste or create a specific sensation, such as a cooling effect with menthol.

Softeners and Texture Additives

Softeners, such as glycerin or vegetable oil, are used to blend the other ingredients and help prevent the gum from becoming hard or stiff. They also play a crucial role in achieving the ideal texture, which is influenced by factors like the gum base, wax, and resin components.

In conclusion, understanding the ingredients in chewing gum sheds light on the fascinating science behind this everyday product. With a blend of natural and synthetic components, sweeteners, flavorings, and texture enhancers, the final product is a flavorful, chewable delight.

Gum Manufacturing and Historical Context

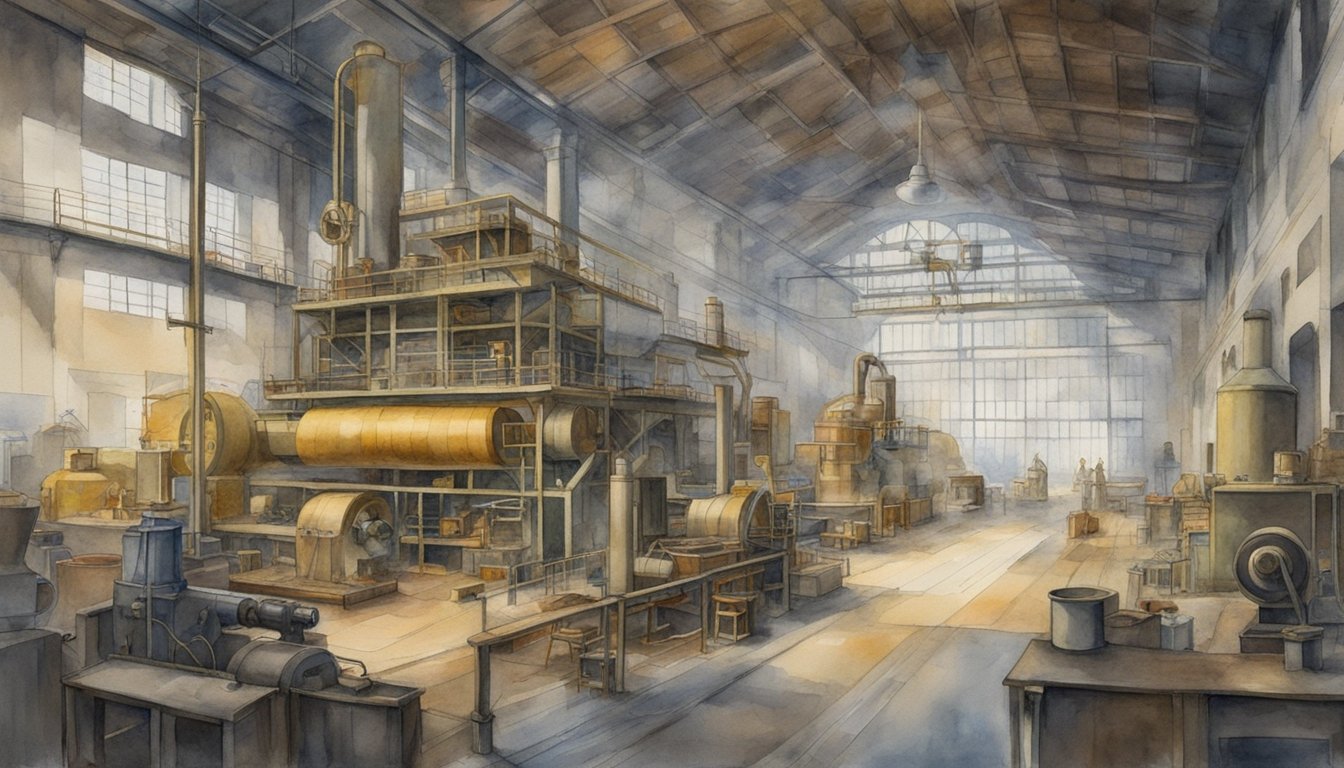

The Gum Production Process

The process of making chewing gum starts with the main ingredient, gum base, which can be derived from natural sources like chicle or synthetic materials. Chicle, a natural gum obtained from the sapodilla tree, was initially used as the primary ingredient for making chewing gum. However, with advancements in technology and increasing demand, most gum bases are now made synthetically.

Gum bases are mixed with sweeteners, flavors, and colors to create an appealing product. This mixture is then heated and molded into the desired shape before being cooled and packaged. Some chewing gums are individually wrapped, while others are sold in packs.

Historical Evolution of Chewing Gum

Chewing gum dates back to ancient times when people chewed different substances for various purposes. The Maya and Native Americans indulged in chewing chicle, while the ancient Greeks chewed the sweet resin of the mastic tree. The practice persisted into the Neolithic period.

Thomas Adams, an American inventor, discovered the use of chicle as a gum base in the 19th century and patented his invention. This marked the beginning of the modern chewing gum industry. Since then, chewing gum has evolved in various forms like Wrigley’s Spearmint and Dubble Bubble.

The chewing gum industry grew further during World War II, when soldiers found it useful for relieving stress and improving concentration.

Health Aspects and Regulations

Chewing gum manufacturers often include sugar alcohols, such as xylitol and sorbitol, to replace sugar and provide a sweet taste without the negative oral health effects. The American Dental Association supports the use of sugar-free gum, which may help in reducing the risk of cavities.

However, chewing gum is still subject to health regulations to ensure consumer safety. These regulations cover aspects like ingredients, quality control, packaging, and labeling. To maintain freshness and quality, chewing gum packages often include an expiration date.