Understanding Salinity and Desalination

When salt dissolves in water, it breaks down into positively and negatively charged ions. These ions, primarily sodium and chloride, increase the salt content of the water, making it saline. But saline water isn’t just about sodium chloride; it also includes other salts like those of calcium, magnesium, and potassium chloride.

Desalination is the hero here, swooping in to remove salt from the water to make it suitable for human use. It’s like a bouncer at the door of a club, allowing only the VIP fresh water molecules to enter and leaving the salty riff-raff outside. Desalination tackles high salt content water, commonly from the ocean, also known as seawater, and separates the salt to produce safe levels of drinking water.

There are a few ways to tell that salty water to “take a hike!” Membrane processes like Reverse Osmosis push water through a filter that’s mean to ions (in a good way), catching them in the act and only letting the fresh water through. Another method, thermal desalination, uses heat to evaporate water, leaving the salt behind because it’s just not into vapors.

One must consider that the sodium content in water contributes to taste and health. While drinking water needs just the right amount of minerals, too much salt can turn it from refreshing to unpalatable quicker than one can say “pass the water pitcher.”

What’s super cool is that scientists are continually searching for new, energy-efficient methods to desalinate the bounty of saltwater covering our planet. They’re like culinary geniuses, tweaking the recipe until they find the perfect balance for that delicious glass of H2O.

Desalination Techniques

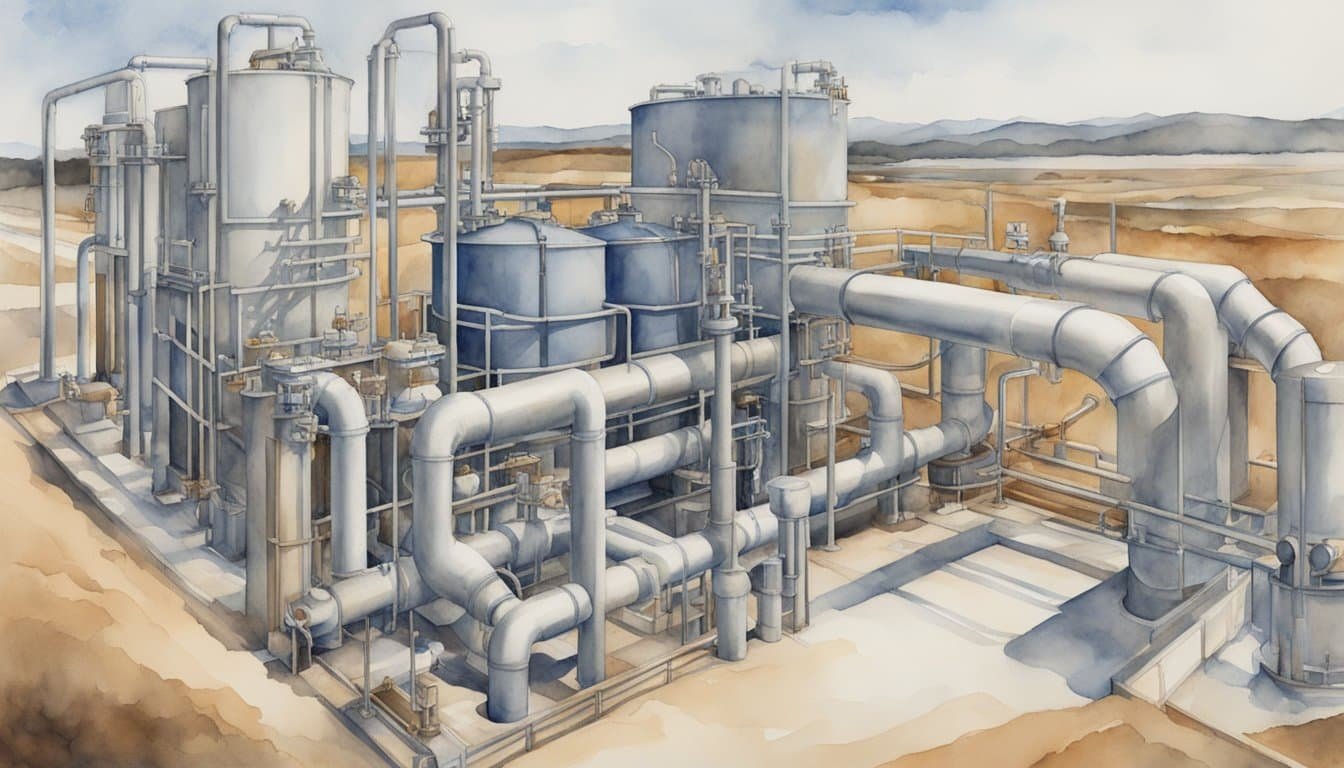

Desalination harnesses various technologies to transform saltwater into drinking water, stripping away salts and other contaminants. From household at-home reverse osmosis systems to larger-scale operations, the goal is clear: to remove salt from water effectively and efficiently.

Reverse Osmosis

Reverse Osmosis (RO) is one of the most common methods used to purify water. A permeable membrane acts as a selective barrier, allowing only water molecules to pass through while salt, viruses, and other impurities are left behind. An RO system applies pressure to push water through this membrane, resulting in clean water on one side and concentrated contaminants on the other.

- Process: Apply pressure → Water passes through membrane → Salt and contaminants are separated

- Use: Widely used in both residential and commercial settings

- Equipment needed: RO unit with pre-filters, membrane, and pressure system

Distillation Process

Distillation is akin to a simple science experiment: boil saltwater in a pot, capture the water vapor through condensation, and collect pure distilled water in a separate container. Heat evaporates the water leaving salts behind, and as it condenses, it’s captured as soft water free from hard water minerals.

- Steps:

- Boil: Heat saltwater until it turns to vapor

- Evaporate: Water vapor rises, salts and chemicals don’t

- Condense: Vapor cools down, condenses back to water

- Collect: Distilled drinking water drips into a clean container

Other Methods

Beyond RO and distillation, there are other methods to consider:

- Ion Exchange: Often used in water softeners to remove minerals that cause water hardness.

- Deionization: Removes ionized salt and mineral contaminants.

- Electrolysis: Uses electricity to separate substances.

- Water Conditioners: Utilize various methods to alter the chemical structure of water, reducing scaling.

Each technology offers a way to tackle salt removal and improve water treatment, catering to different needs, from your morning glass of water to agricultural and industrial applications.

Removal of Salt for Consumption

Removing excess salt from water is crucial before one can chug a glass safely. For folks aiming to enjoy drinking water without the extra sodium kick, there are nifty ways to desalt the H2O. Humans need to manage their salt intake because too much can send blood pressure soaring.

Electrodialysis is a technique that pulls out the salt ions from water with electrical wizardry. Imagine a superhero fighting off bad salts with lightning! This method is suitable for treating produced water—that is, water that’s a byproduct of industrial processes.

Here’s the deal with sodium levels: The U.S. Environmental Protection Agency recommends that drinking water contain no more than 200 mg/L of sodium for it to be considered safe. This is way less than what you’d find in seawater!

For the DIY scientists at home, there’s more to explore, like dehydrating sea salt to bid farewell to hydrate water. By doing this, one can snag water from saltier sources and render it fit for human sipping.

And what about tiny marvels like carbon nanotubes (CNT)? When used in flow-through capacitors, these minuscule tubes are mighty warriors against salt. A CNT setup can reduce salt content effectively—energy-efficiently too!

To add, folks have been working on materials that adsorb salt out of the water like a sponge. That means less salt in the water, more smiles at the dinner table.

Last but not least, the jazzy-sounding capacitive deionization (CDI) might remind you of a sci-fi gadget. But, it’s a real deal breaker when it comes to nixing both salt and unwanted organic visitors from water.

In short, turning seawater into a delicious, safe gulp doesn’t have to be a salty ordeal. With some clever tech and chemistry, one can take the salt out and leave just what’s needed for a refreshingly unsalty sip.

Practical Considerations and Maintenance

When attempting to remove salt from water, whether to desalinate water for drinking or treating wastewater, maintenance is a key factor for the longevity and performance of the purification system. A common method is ion-exchange, a process where unwanted mineral ions are swapped with more desirable ones. Careful monitoring is required as the ion-exchange resin can become exhausted over time and requires regeneration.

A pivotal component in many systems is the brine tank. It requires regular checks to ensure that salt levels are adequate for the regeneration process. Here’s a quick checklist for maintenance:

- Inspect the brine tank for salt levels and bridges

- Clean the tank to prevent dirt and sediment accumulation

- Monitor the resin bed for any signs of fouling

Another consideration is the speed up of clean water production. Advanced membrane technology can improve efficiency but also calls for routine maintenance. These membranes can be prone to scaling or fouling, and need regular cleaning to maintain their efficacy.

Here is a simple table for a typical maintenance schedule:

| Component | Check Frequency | Maintenance Task |

|---|---|---|

| Brine Tank | Monthly | Check and refill salt |

| Ion-Exchange Resin | Bi-Annually | Regenerate the resin bed |

| Membranes | Quarterly | Clean to prevent fouling |

Even materials like glass in sight gauges should be kept clear to ensure operators can monitor the process effectively. Regular, proactive maintenance ensures all these components work together smoothly, preventing costly repairs or inefficient water treatment. Remember, a well-maintained system is the key to keeping our water clean and our glasses full!